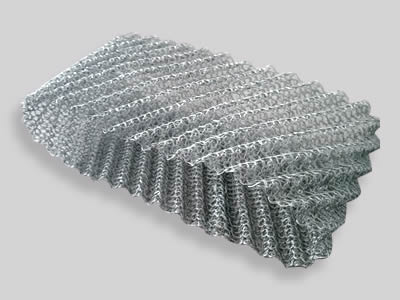

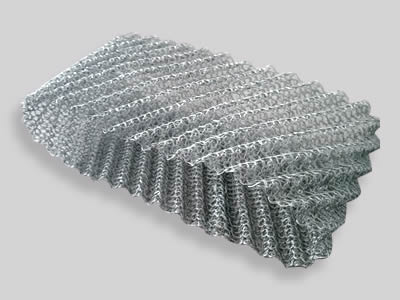

CCMW-01: Ginning knitted wire mesh of catalytic converter mesh wraps for shock and vibration absorbing.

As we all know, the automobile exhaust purifier is one of the most important device in the system. It can purify the harmful gas and reduce gas emission. The catalytic converter is made of ceramic honeycomb brick, which is very fragile. So, we need to take measures to protect it. Catalytic converter mesh wraps are specially designed for this purpose.

Catalytic converter mesh wraps has two types: ginning knitted wire mesh and compressed knitted wire mesh. They all have excellent shock and vibration reduction performance which can protect the catalytic converter mesh wraps from vibration and shock. The material selection of catalytic converter mesh wraps are very strict because they will bear the high temperature and corrosive exhaust gas.

CCMW-01: Ginning knitted wire mesh of catalytic converter mesh wraps for shock and vibration absorbing.

CCMW-02: Compressed knitted wire mesh of catalytic converter mesh wrap for sealing.

The main materials of catalytic converter mesh wraps are stainless steel in different grade of high nickel content alloy materials. Detailed materials are as follows:

The different materials are produced into knitted wire mesh and then crimped into ginning knitted wire mesh. Cover the catalytic converter using ginning knitted wire mesh for shock and vibration absorbing. Sometimes, the ginning knitted wire is in conjunction with an integral strip of intumescent mat material for easy fitting to the ceramic brick.

The compressed knitted wire mesh can be installed on the both end of the ceramic brick for sealing. In this way, the catalytic converter mesh wraps can help the ceramic brick improve the purifying efficiency.

Features of catalytic converter mesh wraps

Applications of catalytic converter mesh wraps

CCMW-03: Ginning knitted wire mesh covering the ceramic honeycomb brick.

CCMW-04: Compressed knitted wire mesh covering the ceramic honeycomb brick.