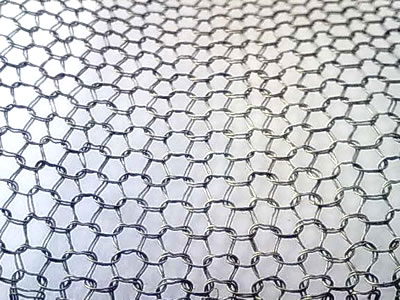

KMF-01: Stainless steel knitted mesh fabric.

Knitted wire fabric is a wire fabric, which is made by a circular knitted machine. The various knitted material wires are knitted into a sleeve of continuous stocking of inter-linked wire loops.

The knitted mesh fabric has various materials, the main materials can be galvanized wire, stainless steel wire, copper wire, brass wire, nickel wire, monel wire and other alloy wires.

KMF-01: Stainless steel knitted mesh fabric.

KMF-02: Copper knitted mesh fabric.

Knitted mesh fabric is normally knitted from round or flat wires ranging from various diameters. The round wire knitted mesh fabric is the most widely used type and the flat wire knitted mesh fabric can be used in the special applications according to customers' requirements.

KMF-03: Round wire knitted mesh fabric.

KMF-04: Flat wire knitted mesh fabric.

The knitted mesh fabric can be made of mono-filament wires or multi-filament wires. The mono-filament knitted mesh fabric is simple and economical, the multi-filament knitted mesh fabric has higher strength to suitable heavy duty applications.

KMF-05: Mono-filament knitted mesh fabric.

KMF-06: Multi-filament knitted mesh fabric.

The knitted mesh fabric can be flattened, which is the original appearance of knitted mesh. It can be crimped, which is crimped by machines to form different shapes, width and depth crimps according to customers' requirements.

KMF-07: Flattened type knitted mesh fabric.

KMF-08: Ginning type knitted mesh fabric.

The knitted mesh fabric can be supplied in rolls, sometimes, the knitted wire mesh fabric can be compressed into different shapes according to customers' requirements. This structure allows liquid and gas flowing through. The special knitting increase filtration capability and particle retention capacity of the wire mesh fabric.

KMF-09: Knitted mesh fabric is commonly supplied in rolls.

KMF-10: Knitted mesh fabric can be compressed into different shape.

Details of knitted mesh fabric

Features and benefit

KMF-11: Knitted mesh fabric with high strength.

KMF-12: Knitted mesh fabric with stable structure.

KMF-13: Knitted mesh fabric can be supplied in roll.

Applications of knitted mesh fabric

KMF-14: Knitted mesh fabric has excellent shielding performance for cables.

KMF-15: Knitted mesh fabric can be made into cleaning balls to clean kitchenware.

KMF-16: Knitted wire mesh fabric can be used as mist eliminator to remove droplets.

KMF-17: Knitted wire mesh fabric can be used as cleaning mesh to clean the mechanical parts.

Note:

The wire diameters of knitted mesh fabric can affect the flow, dirt holding capacity and pressure drop. In general, knitted mesh fabric with larger wire diameters allow for higher flow capacity but provides lower dirt holding capacity. And the cost of larger diameter is relatively cheap then the smaller diameters knitted mesh fabric. So, you should balance which one is the most concerned and choose the right knitted mesh fabric for your applications.