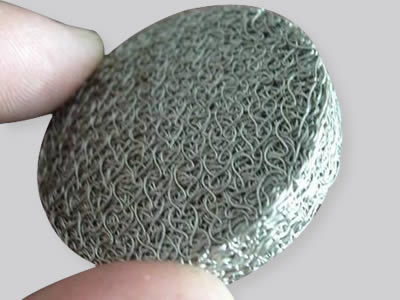

CPKM-02: Stainless steel compressed knitted mesh.

Compressed knitted mesh is a type of multi-functional mesh type. It is made of stainless steel wire, copper wire or brass wire. The various material wires are produced by knitting machine and then compressed by special equipment.

Compressed knitted mesh has a lot of types according to different standard. They are have different materials, wire types, mesh types, shapes, diameters and pressure during compression. We can supply you a wide range of compressed knitted mesh.

Compressed knitted mesh is widely used as filter elements in so many fields, it can also be used for shielding, shock absorption, sealing and other applications.

CPKM-01: Copper compressed knitted wire mesh is widely used in the filtering application.

Different materials

CPKM-02: Stainless steel compressed knitted mesh.

CPKM-03: Brass compressed knitted mesh.

Different wire types

CPKM-04: Round wire compressed knitted mesh.

CPKM-05: Flat wire compressed knitted mesh.

Different mesh types

CPKM-06: Ginning type compressed knitted mesh.

CPKM-07: Flattened type compressed knitted mesh.

Different shapes

CPKM-08: Ring shape compressed knitted mesh rings.

CPKM-09: Disc shape compressed knitted mesh rings.

CPKM-10: Rectangular shape compressed knitted mesh.

CPKM-11: Trapezoid shape compressed knitted mesh.

CPKM-12: Cylinder shape compressed knitted mesh.

CPKM-13: Column shape compressed knitted mesh.

CPKM-14: Oval shape compressed knitted mesh.

CPKM-15: Strip shape compressed knitted mesh.

CPKM-16: Special compressed knitted mesh.

CPKM-17: Special compressed knitted mesh.

CPKM-18: Special compressed knitted mesh.

CPKM-19: Special compressed knitted mesh.

Advantages of compressed knitted mesh

CPKM-20: Compressed knitted mesh is used with perforated metal sheet.

CPKM-21: Compressed knitted mesh is used with woven wire mesh.

CPKM-22: Compressed knitted wire mesh is packaged with brown paper first and then put into the carton box.

CPKM-23: We offer quality compressed knitted wire mesh with standard metal element contents, and each one will be t

Applications of compressed knitted mesh