KMEB-01: Ginning type knitted mesh engine breather.

Nowadays, the environment protection is the most important issue all over the world, with the automobiles popularization, the exhaust gas emission is polluting our environment, so we need to take measures to solve this problem: reduce emission from crankcase breather system.

Knitted mesh engine breather is an ideal material to solve this problem. It is a type of knitted mesh filter installed on the engine breather. It can remove all oil droplets ranging from 3 to 10 microns. In this way, we can reduce the emission and protect our environment.

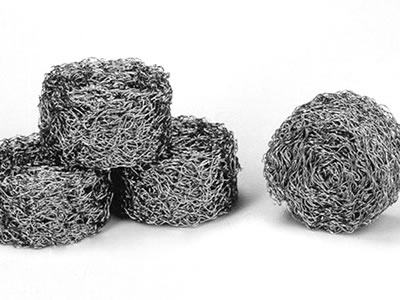

Knitted mesh engine breather is commonly made of high quality galvanized steel wire, and in some high temperature or corrosive environment, the stainless steel wires are available for customers' choice. The knitted mesh engine breather is commonly in rolls, you can cut it into different shapes, and the knitted mesh engine breather can be compressed or crimped into different shapes to suit more engines or breathers.

KMEB-01: Ginning type knitted mesh engine breather.

KMEB-02: Compressed type knitted mesh engine breather.

Features of the knitted mesh engine breather

knitted wire mesh used in the engine breather has lots of advantages than other types of filter material, which are failed to reduce emissions.

KMEB-03: Knitted mesh engine breather can be installed onto the three way catalyst to reduce emission.

Applications of knitted mesh engine breather

Knitted mesh engine breather is mainly used to filter the oil or moisture droplets and reduce emission. Thus, we can protect the air environment in our earth.