Flat knitted mesh wire diameter inspection

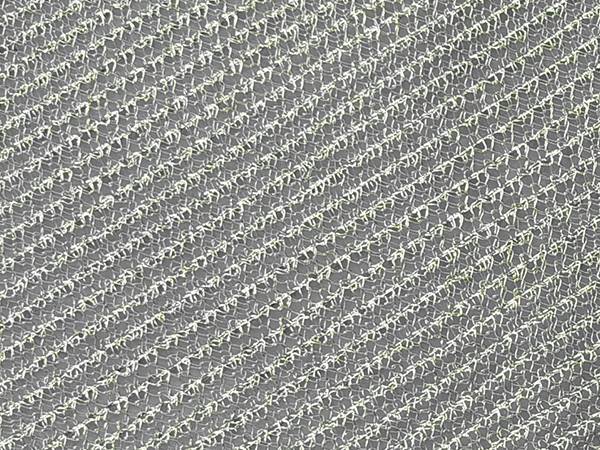

In hydrogen production industry, knitted mesh is often used in polymer electrolyte, proton exchange membranes (PEM), ion exchange membranes (IEM) and also in the extremely harsh conditions associated with alkaline zero-gap electrolycer applications.

Flat knitted mesh wire diameter inspection

Flat knitted mesh aperture inspection

Compressed knitted mesh diameter inspection

Compressed knitted mesh thickness inspection

Crimped knitted mesh

Crimped knitted mesh details

Tinned copper knitted mesh

Tinned copper knitted mesh wire diameter inspection

Flexible & Malleable

Energy Absorbing

Variable Porosity

Harsh Environments

High Resilience

High Strength

Encapsulates & Protects

EMC & RFI Shielding

Cost Efficient

Electrically Conductive

Environmentally Friendly

Material Versatility

High Surface Area

In the process of hydrogen production, electrical resistance within electrolyzers reduces their efficiency and increases operating costs. In conventional designs, knitted mesh is in direct contact with bipolar plates, expanded metal and other additional components.

In response to the industry drive for enhanced efficiency, Boedon adopts mesh-jointing technology to weld knitted mesh to every contact point of metal plate or adjacent components (bipolar plates, expanded metal, etc.) to form a single bonded structure.

This welding process produces an homogenous joint that reduces internal cell resistance while significantly improving electrical conductivity.

Knitted mesh voltage vs current density

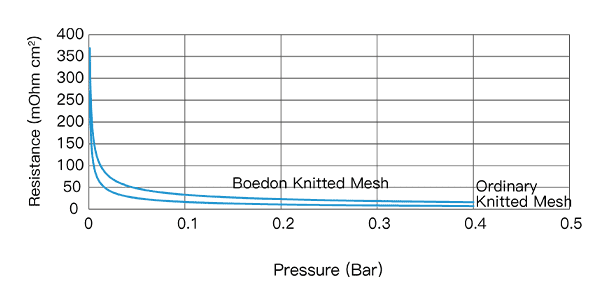

Knitted mesh resistance vs pressure

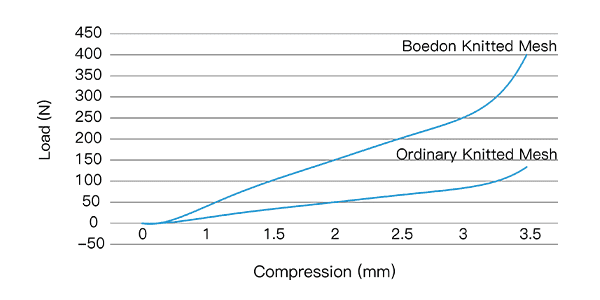

Compressed knitted mesh lately developed by Boedon can effectively extend the service life of electrolyzers and maintain stable operation under thermal cycle and harsh working conditions. It has outstanding levels of resilience and can resistant compressibility losses through load cycling. The 2 charts below display the compression range and performance changes of compressed knitted mesh.

Knitted mesh load vs compression

The change of knitted mesh under load cycling conditions